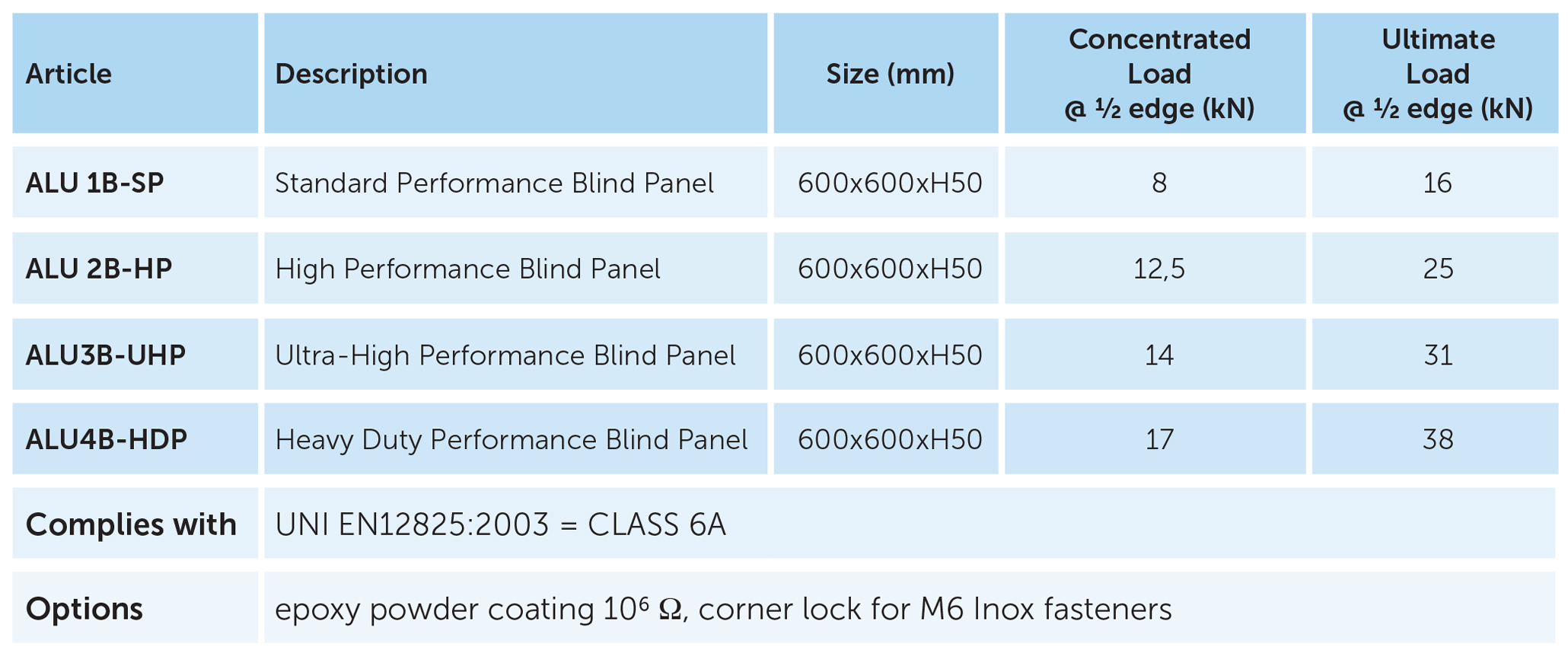

Solid (Blind) Panels 600x600mm

These panels are 600x600xH 50 mm overall thickness (which includes the PVC – 2mm).

The panel is produced by high pressure die casting of an aluminum alloy, as a result of advanced concept die matrix manufacturing.

The panels are predominantly made of solid top cover plate, with interior stiffener ribs, symmetrically positioned and integral to the panel’s surface. The thickness and height of ribs vary to guarantee higher resistance and appropriate load distribution while reducing weight. Each panel is machined to size using computerized numerical control (CNC) machine-driven equipment.

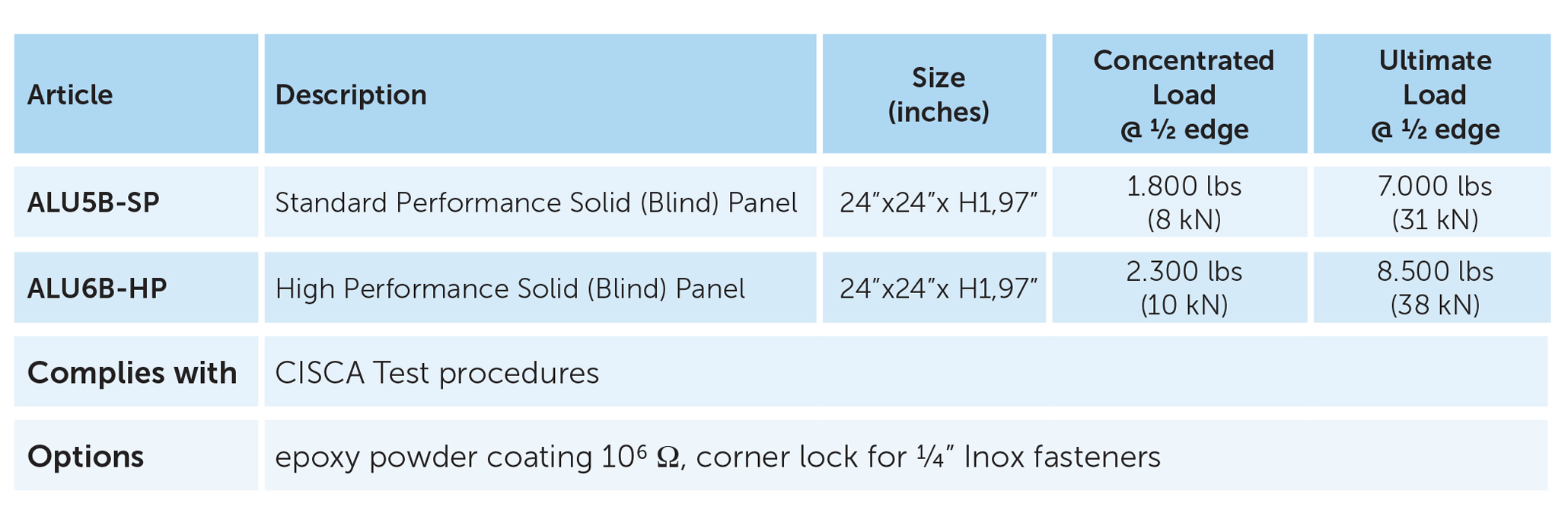

Solid (Blind) Panels 24" x 24"

These panels are 24”x24” and 1,97” overall thickness (which includes the PVC – 0.078”-).

The panel is produced by high pressure die casting of an aluminum alloy, as a result of advanced concept die matrix manufacturing.

The panels are predominantly made of solid top cover plate, with interior stiffener ribs, symmetrically positioned and integral to the panel’s surface. The thickness and height of ribs vary to guarantee higher resistance and appropriate load distribution while reducing weight. Each panel is machined to size using computerized numerical control (CNC) machine-driven equipment.