The raised flooring system “Clean & Heavy-Duty system” was created in compliance with the strict quality requirements of indoor controlled environments. Specifically, according to UNI EN ISO 14644-1, through to ISO 1. The specifications of ALU series panels used by this system, such as load capacity, corrosion resistance, condensable volatile material emission levels, make it a valuable tool that can also be used where chemical process are involved and in cleanrooms.

The panels are aluminum diecast, with standard sizes of 600mmx600mmxH 50mm and 24″x24″xH 1.97″ for the North American market. They offer precise tolerances and high load capacity.

The panels are installed on specific modular support structures, with elevation heights that vary from 250 mm to over 1000 mm (10” up to 39,50”) Finished Floor Height (FFH). Greater elevations achieved via specialized Understructure.

The panels are available with different finishings:

- PVC Vinyl Tile (2-mm/0.078”), Static Dissipative (SD) or Electro Conductive (EC) applied on the upper side by means of conductive glue

- Conductive epoxy powder coating

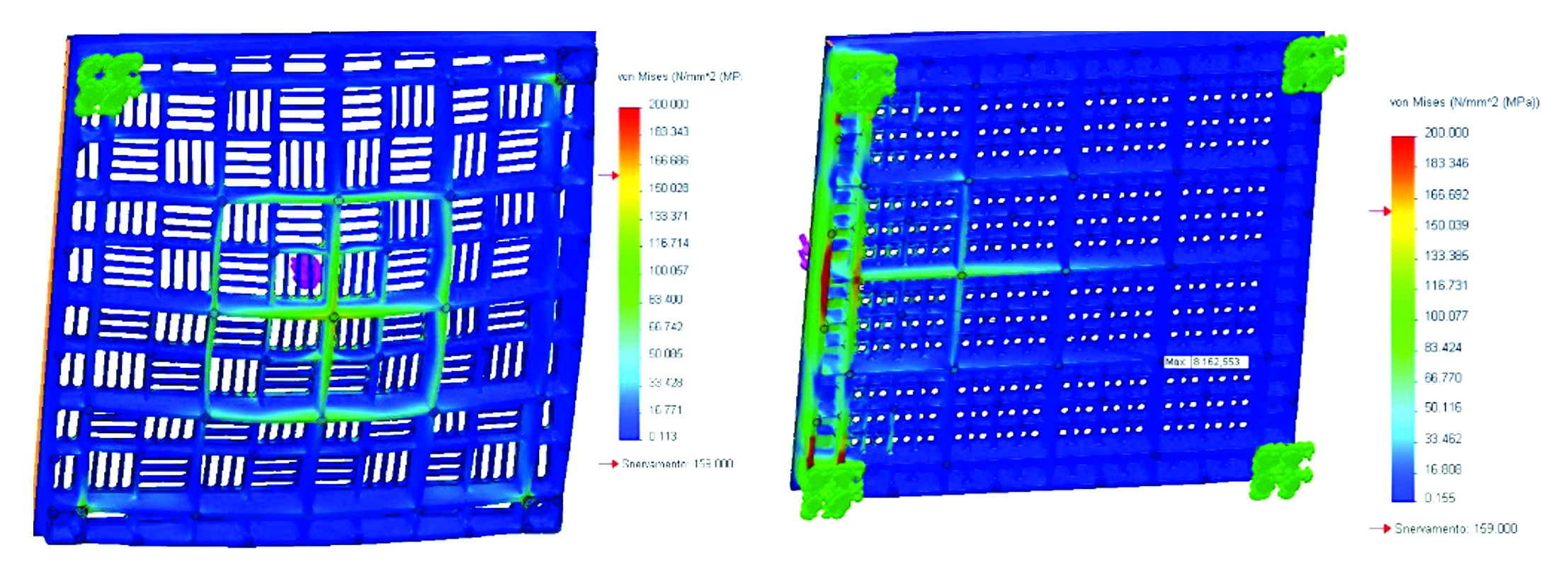

The specifications of these aluminum die cast panels are non-magnetic, high load capacity, durable and highly conductive (current), incombustible (EN13501-1/ EN13501-2).

The ALU series panels are specifically designed for air conduction to guarantee high levels of air purity within the classified area. They are designed to be perforated or grates, to modulate airflow according to requirements and free air capacities of each type of tile.

The support structure of the raised flooring panels is made of Aluminum or Steel pedestals that can carry an axial weight load more than 110kN (25,000 lbs). They are designed with a square base (Aluminum or Steel), a head, a threaded stud (Aluminum or Steel), an adjustment nut, a diecast aluminum collar, and an Aluminum or Steel tube base.

If required, it is also possible add to the support structure, Aluminum stringers and/or Aluminum diagonal bracing.

The support structure can be finished with an epoxy coating that is conductive and resistant to chemicals agents. To reduce vibrations, the heads are equipped with a dissipative compound EVA gasket.